With the updated classification of medicinal psilocybin (medicinal mushrooms) and MDMA in Australia effective since 1st July 2023, authorised psychiatrists are now able to prescribe these substances for certain mental health conditions. The ‘growing’ focus on using psychedelics as a form of alternative medicine within the pharmaceutical industry simply cannot be ignored.

Psychedelics have been used by Indigenous peoples for centuries, but only became a focus for Western researchers within the past 10-15 years after their underlying potential was discovered.

MineARC’s goal is to enable various industries to achieve their organisational goals with the support of our products. In the case of the Little Green Pharma – RMS (LGP) project, they required a multi-room walk-in cleanroom that required design input from both the client as well as a cleanroom specialist. The chamber was also required to be GMP compliant.

Considerations

- Mushrooms are highly susceptible to contamination and need to be grown in a sterile environment.

- Cross-contamination of mushroom spores with other cleanroom facilities was a critical concern

- Pressure differentials for each room required

- Sterilization area for mushroom growth substrates required

- Chamber size restrictions

The Growing Concern

With contamination or ‘contam’ listed as the leading factor of crop failure when cultivating mushrooms, the importance of sterile substrates was paramount when developing harvests for medicinal purposes. As mushrooms produce spores, airborne contamination also poses a large risk for contamination.

With this in mind, LGP ascertained that it was pertinent for their new venture into psilocybin to not interfere with their already well-established medicinal cannabis research facilities. LGP therefore needed a chamber that could facilitate the growth of their mushrooms, while maintaining varying levels of humidity, lighting and temperature for each room within the chamber. Along with this, a containment area was needed that would eliminate the possibility of cross-contamination between the various rooms within the chamber. With all these requirements in mind, it became clear that a combined cleanroom as well as a grow-room was necessary.

The difficulty with combining these two functions was that each room needed independent temperature and humidity control.

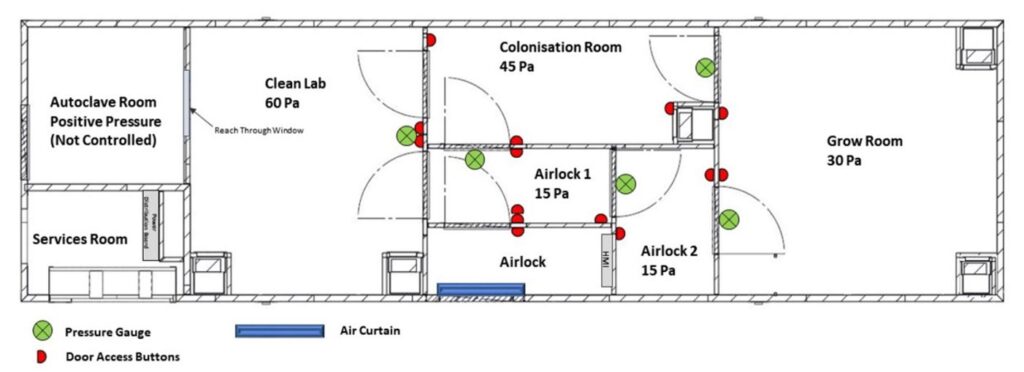

The chamber needed to house six rooms with pressure differentials and air-change requirements that could run independently while still creating the needed isolation for each room within the pressure parameters and simultaneously be ISO:7 compliant to International Cleanroom/Clean Zone Standards.

The Solution

- Custom-built Biora Mushroom Chamber

- Portable walk-in cleanroom & grow-room

- Individual airlocks for each room

- Multi-room chamber

- Expandable design

Regulating Multiple Variables

To ensure the chamber was truly ISO 7 & 8 compliant according to International Cleanroom/Clean Zone Standards (ISO:14644), various engineering elements needed to be factored into the use of the chamber.

The entryway included an Airlock utilising MineARC’s HVAC system as well as an air curtain, and a built-in HMI. Serving as the room where the most contaminants could be found, it was important to only have one doorway that led to the airlock area.

The doorway placement throughout the chamber took into consideration that people and contaminants are not able to move from the cleanest room (clean lab area) directly to the room with the most contaminants (airlock area).

This was done through means of pressure differentials in the six rooms, as well as a magnetic lock system on seven of the nine doors; which would not allow more than one door to be open at the same time.

Along with the different rooms, the chamber was split into four individual zones (excluding the airlock zones):

- Autoclave room – with a positive pressure system

- Clean Lab – ISO 7 with the highest pressure (P:60)

- Colonisation room – ISO 7 with the second highest pressure (P:45)

- Grow room – ISO – 8 with the third highest pressure (P:30)

The autoclave room also helped LGP to sterilise the growing substrates for the research projects by means of the built-in passthrough hatch that led directly from the autoclave room to the clean lab.

The mushroom harvests also required particular humidity levels, however with humidity comes water – a potential contaminant and host to unwanted bacteria.

To mitigate the posed threat that the water system created, a constant flow was engineered, ensuring that the water is filtered at all times through the built-in ring main system. To complement the water system as well as the cleaning needs of the research chamber, a dedicated drain control system was installed that would eliminate any contaminants or inputs from the water system.

Design Factors

MineARC took the following design factors into consideration to assist with the research facility’s needs:

- Flooring: Medical-grade flooring was a critical requirement, yet it also needed to act as a visual queue to alert the team members of the pressure differentials within each room.

- Cleanability: Sterilisation and cross-contamination remained an important element when designing the chamber internals. MineARC also reduced the use of right angles where possible, to mitigate places for dust to gather. The rooms also had rounded corners from ceiling to floor to allow for ease of cleaning.

- Accessibility: It was necessary for servicing components of the chamber to be completely independent from the internals of the chamber. (ie. accessed from outside), ensuring any risk of contamination was mitigated.

- Flexibility: During the design phase, it was necessary to ensure that the chamber was sizeable enough to sufficiently house harvests large enough for research purposes while remaining compact enough to fit into the existing research premises. Additionally, the chamber needed to have the potential to be expanded if required.

Tests and Compliance

As a result of the careful considerations and engineering efforts to have the chamber ISO compliant, it successfully passed the following tests:

- ISO7:7/8 level certification

- HEPA Filtration Integritiy test – with a 99.99% hospital grade

- NATA Particulate test

Cultivating Solutions

Chamber designs and layouts can be customised as needed and fit for purpose. With the medical industry taking a more natural approach while remaining sustainable, it is more important than ever to help researchers obtain enough data for their plant-growth projects to create conclusive evidence of the potential medical benefits.

Biora chambers act as contained environments with customisable variables that can assist with project needs and crop outputs in a fraction of the time.

By investing in this chamber, LGP – RMS was able to produce successful harvests with the full temperature and humidity control they needed.

An unexpected benefit of this portable chamber was that it enabled LGP to transport the chamber to various premises’, which lends itself to the extra security needed for projects of this nature. It also meant that they could train potential staff how to use the chamber without knowing where the final research facility location would be.

Key Takeaways

- Biora chambers are highly customisable

- The multi-room layout enables the structure to house several independent clean spaces that serve different purposes within the mushroom cultivation process.

- Natural alternatives to medicines, such as psychedelics, are becoming more prominent for the treatment of PTSD and depression.