Portable Walk-In Grow Chambers

Portable Walk-In Grow Chambers by Biora provide the agricultural and biotech industries with a portable and flexible solution to controlled environment requirements.

Walk-in grow chambers provide the control and repeatability needed to efficiently sustain precise conditions that can facilitate any agriculture

or research outcome.

They are available in a range of models, engineered specifically for plants at various grow stages. Chambers are customised during the design and manufacturing process to suit client requirements, and can even be built in around existing research or live laboratory equipment.

Product Enquiry

Portable Walk-In Grow Chambers Form

Portable Walk-In Grow Chambers Form

"*" indicates required fields

Portable Walk-In Grow Chambers (Also known as 'Pre-Built')

Biora portable chambers are pre-built at one of MineARC’s three manufacturing locations, then shipped to the site, ready for immediate use.

Ideal for both outdoor and indoor locations (with enough access), the fully portable unit is designed to be plug and play; with minimal on-site installation work required.

The robust structure features insulated panelling; based on the expected external temperature in order to ensure it can maintain the required internal conditions. Road transportable thanks to integrated lifting lugs; each chamber undergoes in-house analysis to ensure compliance with local building codes for lifting and roof loads.

Features

- Standard skid width of 3.5m (11.5’)

- Custom length and height

- Custom internal layouts including: Single bay, Double bay, Multi-room

- Research-grade upgrades available

Standard Grow Room Features

- Range of standard and custom configurations available

- Robust steel construction with insulated panelling

- Industry-leading HMI with intuitive programming, monitoring and control

- Remote web-based chamber monitoring and control

- CO2 monitoring and enrichment, with optional gases available

- Precise temperature and humidity management

- Ducted ventilation for air flow manipulation

- Security and data protection options

Walk-in grow chambers provide the control and repeatability needed to efficiently sustain precise conditions and maximise production capabilities, product quality and security. These grow rooms can also be engineered to comply to with the necessary standards for research-based applications.

Applications that would benefit from a grow room include:

Vertical Farming Solutions

Vertical farming is increasingly playing an important role in any country’s food security policy, including a means to supplementing traditional

farming supply chains. This is particularly relevant when it comes to high value crops and seasonal produce.

With prevalent issues such as climate change, loss of arable land and a global population set to reach 10 billion by 2050, vertical farming offers

the flexibility of growing food close to the point of consumption; with less reliance on inputs such as water, fertilisers and chemicals when compared to traditional agricultural methods.

Biora’s specialised vertical farming design provides an uniquely competitive advantage with regards to crop volume; by providing more space, better redundancies and guaranteed consistency when compared to other containerised farming solutions.

Vertical Farming Features

- Robust construction with insulated paneling

- Customisable grow room configurations allowing segregation of grow, mechanical and preparation areas

- Individual monitoring and dosing within each grow zone to allow tailored plant growth recipes

- Intuitive HMI control system with customisable programs, data logging and remote access

- CO2 monitoring and enrichment options

- Uniform temperature and humidity control

- Optimised energy efficiency by controlling light intensity and day length across different grow zones

- Independent airflow control within each grow zone, to expedite the growing process

- Water purification and sterilisation process to reduce risk of water borne pathogens

- Expert grower advice to ensure crop success

Exterior

1200L Biora Reach-In Chamber

Steel Frame

HMI Interface

Viewing Window

Sealing Door

Interior

Insulated Panel & Steel Frame

HVAC & Airflow Control

Sealed Door

HMI Control System

Adjustable LED Lighting

Outdoor Plant Growth Chamber Extends Research Capabilities

Major Considerations

Lighting

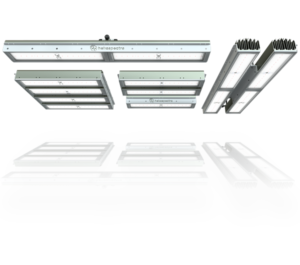

Mitra X

Featuring a modular design, an innovative cooling solution, and IP67

dust and water resistance, MITRA X is any growers dream come

true. Designed to work both indoors and in greenhouses, MITRA X is

available in a host of different modules and spectral options making

it the most versatile and efficient LED grow light on the market.

Featuring a modular design, an innovative cooling solution, and IP67

dust and water resistance, MITRA X is any growers dream come

true. Designed to work both indoors and in greenhouses, MITRA X is

available in a host of different modules and spectral options making

it the most versatile and efficient LED grow light on the market. HELIOCORE

HelioCORE takes the guess work out of advanced lighting control.

Apply custom lighting strategies, make adjustments based on

predictive algorithms and enjoy complete control over intensities

and spectra from any type of device.

HelioCORE takes the guess work out of advanced lighting control.

Apply custom lighting strategies, make adjustments based on

predictive algorithms and enjoy complete control over intensities

and spectra from any type of device. ELIXIA

ELIXIA is an essential tool for any greenhouse or indoor operation

seeking to deliver superior crop quality. Featuring up to four

tuneable wavelengths, variable light intensities, and exceptional

build quality, ELIXIA allows you to apply crop-specific lighting

strategies via primary and secondary optic lens plates.

ELIXIA is an essential tool for any greenhouse or indoor operation

seeking to deliver superior crop quality. Featuring up to four

tuneable wavelengths, variable light intensities, and exceptional

build quality, ELIXIA allows you to apply crop-specific lighting

strategies via primary and secondary optic lens plates. DYNA

Featuring nine individually controlled wavelengths ranging from

380nm (UVA) to 735nm (Far-Red), DYNA is without question the

worlds most flexible LED grow light. Designed with plant scientists

in mind and with infinite spectral options, DYNA is at home in any

research or agtech environment.

Featuring nine individually controlled wavelengths ranging from

380nm (UVA) to 735nm (Far-Red), DYNA is without question the

worlds most flexible LED grow light. Designed with plant scientists

in mind and with infinite spectral options, DYNA is at home in any

research or agtech environment. Floor Plan

HMI - Control and Security

Biora’s industry-leading control system allows for intuitive programming and web-based management. Enjoy real-time monitoring of all control processes, with the ability to access 12 months’ worth of historical data remotely or via the local HMI screen.

The Biora Control System provides the added advantage of security within the chamber. A number of optional security access solutions are available to protect your investment including:

Biora’s industry-leading control system allows for intuitive programming and web-based management. Enjoy real-time monitoring of all control processes, with the ability to access 12 months’ worth of historical data remotely or via the local HMI screen.

The Biora Control System provides the added advantage of security within the chamber. A number of optional security access solutions are available to protect your investment including:

- Electric smart key lockable door with PIN code or swipe access

- External IP cameras installed for both security and remote chamber monitoring

- Internal temperature, humidity, and pressure sensors

- Easy integration with any existing building management system

Features

- Web-based software with both local and remote access

- Real-time monitoring of all control processes

- 12 months of historical data accessible

- Limitless customizable programs

- Customized HMI options and local engineering support

- Data export and import options

- Multiple language support

- Push notifications based on custom alert settings

- Data protection and security options

Laboratory Standards Compliance

Biora Walk-In Chambers can be engineered specifically to meet laboratory specifications and standards; including physical containment, bio security and ISO certifications. MineARC Engineers have experience in developing PC2 and BC2 compliant, purpose-built chambers to meet these stringent requirements.

Biora Walk-In Chambers can be engineered specifically to meet laboratory specifications and standards; including physical containment, bio security and ISO certifications. MineARC Engineers have experience in developing PC2 and BC2 compliant, purpose-built chambers to meet these stringent requirements.

Features

- Anteroom

- Coved walls and flooring

- Bio-security, anti-static vinyl flooring

- Cleanroom-grade insulated paneling

- HEPA filtration

- Plenum to control air distribution (unidirectional and non-unidirectional)

- Concealed ducting and electrical

Construction and Insulation

All exterior walls of the Biora Walk-in Growth Chamber are constructed of XFLAM insulated panels, composed of a polyurethane foam core. With a high thermal insulation capacity, the panels will meet the most demanding temperature control requirements; however are available in higher R-Values for extreme climates.

With excellent aesthetics, the panels are easily washable and resistant to chemical spills and corrosion.

Doors

MineARC offers a range of entry and exit options, designed to suit the requirements of a Biora Walk-In Chamber.

They are available in two configurations – swinging or sliding; with drop seals and air curtains as an optional inclusion for cleanrooms and

research-grade specifications.

Other options include observation windows, keyed magnetic locks and security ID systems.

Flooring

Our vinyl flooring is designed to meet the required specifications of each particular chamber, with various grades and colours available.

Flooring is standard on all clean rooms for a hospital-grade result; including coving and high to walls, as well as a specialised corner system

designed to reduce dirt build up.

HVAC and Air Flow

Biora Walk-in Chambers are fitted with specialist HVAC, utilising either air or water cooled systems. All ducted systems are accessible via a

roof plenum to enable easy maintenance and repairs.

The Biora HVAC system has been specifically designed to ensure it can reliably control the environment to satisfy any research-grade

application. Rooms can be controlled as a single zone, or individually; ideal for eliminating micro-climates or enabling different grow areas to

maintain varying temperature, humidity and airflow gradients.

Our Biora chambers are engineered to achieve the correct airflow required for your project – whether it’s unidirectional or non-unidirectional;

horizontal or vertical. A range of filter options including HEPA filtration can be included in the chamber build.

Control Options

Carbon Dioxide and Other gases

The monitoring and control of oxygen (O2), carbon dioxide (CO2) and nitrogen (N2) is an optional feature of all Biora Walk-In Chambers. For rapid CO2 removal, MineARC scrubbing technology can be utilized to reduce levels within the system to below 250ppm (0.025%). Alternatively, CO2 enrichment can be included within the chamber.

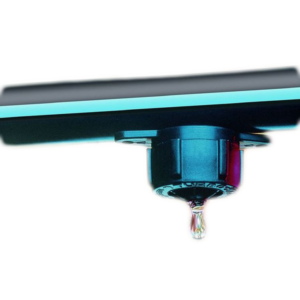

Irrigation and Fertilisation

Automating irrigation improves productivity and plant quality by making irrigation more uniform. MineARC’s drip or ebb flow system can be connected into the HMI allowing different automated irrigation options based on time and light intensity. Different grow areas can have different irrigation rates and frequencies.

Biora Standalone Scrubber

The Biora Stand Alone Scrubber is a compact air regenerative system that ‘scrubs’ carbon dioxide (CO2) from the air within enclosed spaces; allowing for complete control of CO2 levels for research applications. The addition of the system permits an enclosed space that is ventilated from the outside to be converted to a fully isolated, controlled environment.

Related Products

LED Glasses – Biora Method Seven Eyewear

LED Glasses – Biora Method Seven Eyewear LED Glasses for grow rooms, designed by Method Seven, deliver the world’s first glasses formulated to light balance and compensate for the unique spectrum of LED grow lights. Unique LED lens technology and highest quality materials provide exceptional colour and clarity, as well as 100% UV protection. This

HPS Glasses – Biora Method Seven Eyewear

HPS Glasses – Biora Method Seven Eyewear Biora’s HPS Glasses for grow rooms, designed by Method Seven, feature unique mineral glass lenses that deliver perfect colour balancing in the intense yellow spectrum and harsh visual conditions of HPS lighting environments. Tuned and tested for grow environments, Biora Method Seven HPS eyewear is available in a

240L Reach-In Chambers

240L Reach-in chambers DOWNLOAD DATA SHEET Product Enquiry Applications Tissue Culture Incubation Environmental Testing Arabidopsis Algae Growth Plant Growth Specifications Standard Features Single Compartment Insulated, single door Observation window light tight cover, condensation free Biora HMI with LED touchscreen Powder coated Steel exterior Four caster wheels with levelling feet Internal HVAC Stainless Steel or White