This client’s current laboratory faced structural foundation problems and needed more space for expansion. They turned to Biora, given the history of successful projects together with MineARC Systems Refuge Chambers.

With a preliminary layout in mind, the client wanted to replace their North American laboratory with a larger, custom modular chamber. This pre-built solution would avoid lengthy on-site construction. Most of the laboratory was built at our Dallas manufacturing facility, with only the final connections done on-site.

Creating a Custom Modular Chamber Solution

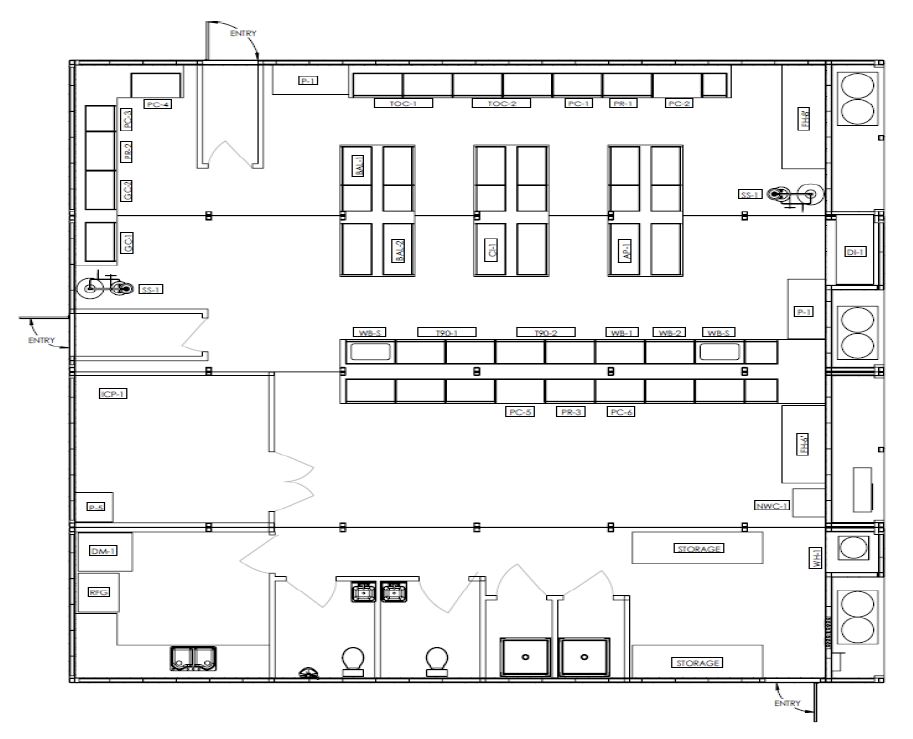

Biora was tasked with designing and constructing a custom modular chamber to fit within a 49’ x 48’ space. The laboratory was supplied in four modules, each measuring 49’ x 12’ x 11’, with entry and exit through two vestibules. The modules were fully customised to meet the specific configuration and equipment needs of the laboratory operators.

From the early stages, Biora and the client carefully planned the workflow for the new laboratory. Weekly meetings between MineARC, Biora and the client established the MEP drawings for the project.

The facility features one large laboratory space with epoxy work surfaces and power drops for all equipment. It also includes two ADA-compliant lavatories and showers.

Additionally, the client required a designated space for a de-ionized water system, and the building was pre-plumbed to connect with various laboratory gas cylinders to support different processes and equipment.

The following customised options were also requested:

- Kitchenette and breakroom

- Separate laboratory space for process-specific use

- 2 x Safety shower and eyewash stations

- 2 x Chemical fume hoods

- 2 x Laboratory sinks

- Several high-capacity corrosive air filters

MineARC & Biora collaborated directly with many of the client’s existing equipment providers and contractors to discuss power, utility, space capacity and other necessary requirements. This helped to ensure that there were no major issues or missed steps.

The Solution

- Working along side the client and the HVAC expert to combat humidity challenges

- Airflow path considerations – to avoid laboratory equipment interference

- ADA compliant space that considered future expansion

The Laboratory Design Process

The design process began with the client’s initial layout requirements, which Biora transformed into a modular solution built at our Dallas facility and then transported to the site. MineARC & Biora coordinated with the client’s civil, structural, plumbing, and electrical contractors throughout the project to ensure a smooth installation when the units arrived.

Throughout the entire project, all parties worked closely with the client’s laboratory operators to ensure the designs met their needs. Direct communication with the end-users allowed Biora’s engineering team to better understand space usage and the required workflow. The existing HVAC system had a humidity issue the client wanted to avoid in the new space. By gathering input from operators and contractors, it allowed Biora to identify and resolve the humidity problem with precise design considerations. Collaboration with the fume hood manufacturer ensured all factors were addressed.

Thanks to the client’s active involvement and the strong rapport between MineARC and the subcontractors, Biora provided a solution that excited all parties involved.

Key Takeaways

- Biora’s custom modular chambers are built fit-for-purpose

- Collaborative efforts are achievable through effective communication

- Feedback from clients is essential for understanding clients project needs